I'm calling it done at this point. After cleaning and repairing the bonus Kurt vise I acquired with the Clausing drill press its ready for use. I built a special base and anti rotation arm to make quick work out of clamping the vise to the drill press table.

The vise base is a .50 thick phenolic plate. I had the material left over from another job and it made sense for this application. Its strong and durable and wont mark the table. It has the perfect amount of friction that allows the vise to move around but is not so slippery that the vise will move under heavy drilling. The vise mounts to the plate via a couple of Helicoiled tapped holes. The notch is for the steel anti-rotation arm. I just scribed around the base of the vise casting and band sawed the profile and notch to match. You can see my chicken sketching on the side of the flat bar arm.

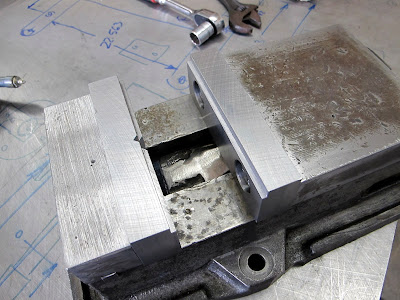

I wanted the anti rotation arm to be one inch wide. All I had in stock was two inch wide material. Nothing is easy right? I band sawed the two inch lengthwise and then milled the edges. Something to note when you do this type of splitting of a rolled bar. The cut immediately opens up and the two pieces come out curved from the stress relieving cut. I have had this happen before so I allowed extra cleanup stock so I would finish one of the bars to one inch wide. The clamps are holding a strong back back bar to keep the narrow bar from vibrating while machining.

So in this shot we see the vise mounted to the base plate and the anti-rotation arm attached. I found a cheap swivel socket wrench at HF that seems to work as a decent replacement for the missing Kurt article.

My McMaster box arrived today so I was able to complete the anti-windmill arm clamp. I think we all have a horror story on the drill press that we could relate. Its nice to not have any roadblocks to doing the right thing with clamping on the drill press.

The clamp allows the arm to slide in and out and pivot when loosened. When the clamp lever is cinched down the vise is locked in place. It can be quickly and easily removed if you need the entire surface of the drill press table for a large part. The Kurt vise is pretty heavy so it makes for a solid drilling experience.

So my famous drill press story goes like this. I was making some special plastic starwheels for a bottle filling machine. These look like big sprockets with teeth the same shape as the bottle being filled. Their purpose is to time and guide the bottles into the filling machine. These particular wheels were made from PVC plastic plate. It takes two star wheels to make a set they are connected by a spacing hub and attached with flat head screws. I needed to countersink the mounting screws after drilling the holes in the plates. We used to make these in the pre-CNC days by carefully pasting a full scale drawing on the material and then band sawing the curves and arms of the star wheel. It took a few hours to do a nice job on these with the sawing, sanding and filing. The mounting holes were one of the last operations.

We did a lot of 316 stainless in that shop so my countersink was pretty hammered. I went and got a brand new countersink from the machinist tool crib to use on my nice new star wheels. I remember it well because it was 3/4 inch in diameter and sharp as a scalpel. I saved a trip on the way back by picking up a flat head screw from the bolt bins to gage the countersink diameter. The mill was being used so I decided to use the drill press in the welding shop to countersink the holes.

Here where it starts to get interesting. I remember saying to myself, "I'll just hold this down by hand to the table" See this is how it starts, one little dumb thing. The next thing I told myself was, "I don't need to set the depth stop, It takes so long to run the damn thing down so far" I chucked up the countersink and set the drill press speed fairly slow.

These things happen so fast it always surprises me. The millisecond the single lipped countersink touched the edge of the pilot hole it snagged and sucked my star wheel plate right off the table. I somehow managed to hold onto the plate but all that did was make the countersink actually drill through the plate. Instead of a countersink for a 1/4 flat head screw I now had a three quarter inch diameter round hole in its place. My butt tightening event was over in about 500 milliseconds.

Every time I need to countersink soft plastic from that point on I either have the part securely clamped, or the cutting tool is non powered. Fortunately for me PVC cements well so I was able to make a plug and glue it in and re-drill and countersink the hole and save the part. With that cement the countersinking lesson was permanently bonded to my hard drive.

Thanks for looking.

Tom Lipton

Ongoing journal of a life spent designing and building special tools, instruments and mechanical devices for the scientific, medical, metalworking and product development industries. Idea's turned into reality by the mechanical pursuits of Tom Lipton (OX)

Monday, August 19, 2013

Thursday, August 15, 2013

Kurt Vise Root Canal

A few articles ago I wrote about a pleasant machinery surprise I found. The surprise was a nice four inch Kurt vise that came with my Clausing drill press for nothing. The vise was pretty hammered when I started working on it. Originally I thought it was an offshore knockoff and even considered trading it away for something else. Lucky for me I decided to give it a bath and take a closer look.

The vise was in pretty sad shape when I started in on it. The jaw mounting surfaces were whupped from clamping parts with no jaws. The handle is lost to who knows where and the replacement is welded in place no doubt to prevent its loss. A fine patina of sulfur based cutting oil residue rounds out the gruesome picture.

The moving nut has seen the business end of too many drill bits to count. One bonus here is the table of the drill press is relatively unmolested. Probably because the vise took the bullet for the team protecting the table. Look closely at the divits on the right side of the nut. They look a little wonky to me so I started picking at them with a awl. I was able to pop out a couple of loose fillings made of epoxy.

A few minutes in the dentist chair and now we have a clearer picture of the necessary dental work. I don't understand how somebody keeps drilling in a situation like this. The one hole at the top of the image goes halfway past the vise screw. I know now why the bozons patched the holes with JB weld or bondo. They had to keep the chips out of the screw or nothing would work.

Many of the edges of the vise were chowdered up like this. A trick a dutch toolmaker showed me a million years ago is instead of filing the raised burr off is to displace the material back into position. You will need a smooth flat faced hammer. Its important that the edges between the face and the side of the hammer are rounded so you don't get a bite mark if you hit off angle.

The trick is to hammer and direct the blows so the face hits flat. If your careful and work slowly generally you can push the material back into position pretty well. If you file it off its gone forever.

A little careful tapping and the corners are mostly back where they belong. Its going to take more than a little tapping with a hammer to get this vise looking good again.

The first step in fixing the Swiss cheesed vise nut was to make a copper mandrel to fit inside the threaded hole through the center. The purpose of the mandrel is so any weld metal doesn't get into the threads. The nut would be difficult to re-thread in the lathe because of its awkward shape and odd size and left hand to boot.

The copper mandrel fits in the threaded bore with a easy slip fit. I expect this to get a little stuck after the welding.

A short preheat and it will be ready for welding. Looking for something like three or four hundred degrees F or so. Hot enough to smoke the old cutting oil.

I'm TIG welding the holes with 1/8 diameter Ni-99 rod. Tungsten is 3/32 diameter Lanthanated DC straight polarity. A reader has been asking me what kind of current I'm running on some of these jobs so I set the camera up and took a picture.

I did it twice and the current was the same at 100 amps. The machine was set in the high range which is the upper scale on the right hand meter.

It took two filler rods to fill the cavities up to this point. If I was really a dentist this would be called a trans-cavity bridge filling.

While it was still hot It got wrapped in a fiberglass blanket and allowed to cool overnight. Next up will be the mandrel removal.

The next day I went to work on removing the copper mandrel. Driving into work I thought of a good way to drive it out by just inserting the lead screw and pushing it out. I was so happy I thought of an easy way to push it out I was thinking about it during the day.

It was a great idea for about half way. The mandrel stopped moving so I had go to plan B and get medieval on it. I ended up cutting if off short and drilling as big a hole as I dared in the now dead soft copper. If you haven't experienced dead soft copper and drill bits consider yourself warned. After drilling a pretty good sized hole through it still wouldn't come out so I used a jab hacksaw to split the copper tube that was left of the mandrel and collapse it into the hole. I didn't take any pictures of this process as I was annoyed and just wanted to get it done.

I did some sanding on the weld buildup to make it look more presentable. It least the holes are patched and no chips will get down into the screw and nut assembly.

The finished product. Not factory new but definitely better than usable. I made a set of steel jaws with a built it parallel step and vertical vee groove. Not a bad ending for a vise that was close to its expiration date. I called Kurt to ask if they had parts for this vise. I was told this vise is a very early model. The clues were the five inch width and the lack of a needle thrust bearing in the screw. This dates it to the dawn of Kurt history. A real relic.

Thanks for looking.

Tom Lipton

The vise was in pretty sad shape when I started in on it. The jaw mounting surfaces were whupped from clamping parts with no jaws. The handle is lost to who knows where and the replacement is welded in place no doubt to prevent its loss. A fine patina of sulfur based cutting oil residue rounds out the gruesome picture.

The moving nut has seen the business end of too many drill bits to count. One bonus here is the table of the drill press is relatively unmolested. Probably because the vise took the bullet for the team protecting the table. Look closely at the divits on the right side of the nut. They look a little wonky to me so I started picking at them with a awl. I was able to pop out a couple of loose fillings made of epoxy.

A few minutes in the dentist chair and now we have a clearer picture of the necessary dental work. I don't understand how somebody keeps drilling in a situation like this. The one hole at the top of the image goes halfway past the vise screw. I know now why the bozons patched the holes with JB weld or bondo. They had to keep the chips out of the screw or nothing would work.

Many of the edges of the vise were chowdered up like this. A trick a dutch toolmaker showed me a million years ago is instead of filing the raised burr off is to displace the material back into position. You will need a smooth flat faced hammer. Its important that the edges between the face and the side of the hammer are rounded so you don't get a bite mark if you hit off angle.

The trick is to hammer and direct the blows so the face hits flat. If your careful and work slowly generally you can push the material back into position pretty well. If you file it off its gone forever.

A little careful tapping and the corners are mostly back where they belong. Its going to take more than a little tapping with a hammer to get this vise looking good again.

The first step in fixing the Swiss cheesed vise nut was to make a copper mandrel to fit inside the threaded hole through the center. The purpose of the mandrel is so any weld metal doesn't get into the threads. The nut would be difficult to re-thread in the lathe because of its awkward shape and odd size and left hand to boot.

The copper mandrel fits in the threaded bore with a easy slip fit. I expect this to get a little stuck after the welding.

A short preheat and it will be ready for welding. Looking for something like three or four hundred degrees F or so. Hot enough to smoke the old cutting oil.

I'm TIG welding the holes with 1/8 diameter Ni-99 rod. Tungsten is 3/32 diameter Lanthanated DC straight polarity. A reader has been asking me what kind of current I'm running on some of these jobs so I set the camera up and took a picture.

I did it twice and the current was the same at 100 amps. The machine was set in the high range which is the upper scale on the right hand meter.

It took two filler rods to fill the cavities up to this point. If I was really a dentist this would be called a trans-cavity bridge filling.

While it was still hot It got wrapped in a fiberglass blanket and allowed to cool overnight. Next up will be the mandrel removal.

The next day I went to work on removing the copper mandrel. Driving into work I thought of a good way to drive it out by just inserting the lead screw and pushing it out. I was so happy I thought of an easy way to push it out I was thinking about it during the day.

It was a great idea for about half way. The mandrel stopped moving so I had go to plan B and get medieval on it. I ended up cutting if off short and drilling as big a hole as I dared in the now dead soft copper. If you haven't experienced dead soft copper and drill bits consider yourself warned. After drilling a pretty good sized hole through it still wouldn't come out so I used a jab hacksaw to split the copper tube that was left of the mandrel and collapse it into the hole. I didn't take any pictures of this process as I was annoyed and just wanted to get it done.

I did some sanding on the weld buildup to make it look more presentable. It least the holes are patched and no chips will get down into the screw and nut assembly.

Thanks for looking.

Tom Lipton

Monday, August 12, 2013

Three Dimensional Imaging Microscope

As part of a development effort on a new high field magnet design we are currently fabricating various parts of a prototype magnet for testing. The magnet is a hybrid design and uses a unique configuration to cancel and or minimize the some of the large forces that want to rip the magnet apart. We call this unique design a canted cosine theta configuration or CCT for short. This is a hollow bore superconducting design that we hope will lead to magnetic fields in the 20T (Tesla) range. So far the results are promising and fun to work on.

In these shots you see the basic configuration of the magnet. These are parts produced by the FDM process and were used to test groove geometry and winding potential. The cable Jim is inserting is a flat multi strand cable of rectangular cross section approximately 1mm x 3mm.

As you can see in the images the Niobium Titanium cable is insulated with a thin glass sleeve or overwrap. The idea is this isolates the wire from the magnet structure electrically. Part of our development project is to determine the groove geometry that protects the wire and insulation during winding and holds the wire securely during operation. Ultimately these might be built using Niobium-tin (Nb3Sn) which will allow higher magnetic fields to be achieved.

Here is an aluminum test mandrel I machined on a 4th axis CNC machine. This particular sample was for winding and insulation testing for a high temperature superconductor (HTS). It is 1.50 inches (38mm) in diameter and the elliptical helical groove is a little over 1mm wide and 1mm deep with a round bottom. During winding tests the edge of the groove damaged the thin insulation so we tried a few quick shop fixes to try and soften the edge.

To help evaluate the changes in groove geometry we used a special digital microscope made by the Keyence company. We have one of these wonderful tools that we can use to examine and measure small features like this groove.

The microscope itself was designed from the outset to be portable and stand alone. The idea was to put an advanced tool out on the shop floor to collect meaningful information with the parts in situ. The variety of lenses allow the user to capture and measure with high magnification and great depth of field. The computer is fully ruggedized and integrated and easily portable with the actual scope. The stage is motorized and allows the computer to control the focus and depth up measuring feature. We didn't use the tilting ability of the stage for what we did here but it has been handy to create three dimensional images or peer into something off axis.

On the mandrel one thing we tried in the shop to gently deburr and soften the edges of the wire groove was wire brushing with a soft bristle wire wheel. The thought was that the bristles would break down the edge and not disturb the groove much.

In this image you can see the effect of the wire brush on the groove. The surface has been roughened by the brush. Unfortunately I didn't get any images before we brushed the mandrel.

Drilling down further at higher magnification we see the edges and lizard skin surface in better detail.

The microscope has a variety of measuring tools for distance, diameter, area etc. One of the more amazing things it can do is three dimensional images. The Keyence VHX does this by taking a set of images depth up and combining them to produce a three dimensional image that can be rotated much like a solid model.

The groove surface and top are both in focus giving a depth of field in this case of around a millimeter at 50x magnification. Images can be stitched together to make a larger seamless mosaic.

This is a three dimensional image of the curved pole section of the test mandrel.

The second thing we tested with this mandrel was a chemical etch to help soften the insulation scuffing corners. It consisted of an acid etch, much the same as a pre-anodizing treatment but without the caustic part of the anodizing process.

In this image you can see the overall improvement of the wire brushed surface in the earlier image.

Link to some other images taken with the VHX system.

Thanks for looking.

Tom Lipton

In these shots you see the basic configuration of the magnet. These are parts produced by the FDM process and were used to test groove geometry and winding potential. The cable Jim is inserting is a flat multi strand cable of rectangular cross section approximately 1mm x 3mm.

As you can see in the images the Niobium Titanium cable is insulated with a thin glass sleeve or overwrap. The idea is this isolates the wire from the magnet structure electrically. Part of our development project is to determine the groove geometry that protects the wire and insulation during winding and holds the wire securely during operation. Ultimately these might be built using Niobium-tin (Nb3Sn) which will allow higher magnetic fields to be achieved.

Here is an aluminum test mandrel I machined on a 4th axis CNC machine. This particular sample was for winding and insulation testing for a high temperature superconductor (HTS). It is 1.50 inches (38mm) in diameter and the elliptical helical groove is a little over 1mm wide and 1mm deep with a round bottom. During winding tests the edge of the groove damaged the thin insulation so we tried a few quick shop fixes to try and soften the edge.

To help evaluate the changes in groove geometry we used a special digital microscope made by the Keyence company. We have one of these wonderful tools that we can use to examine and measure small features like this groove.

The microscope itself was designed from the outset to be portable and stand alone. The idea was to put an advanced tool out on the shop floor to collect meaningful information with the parts in situ. The variety of lenses allow the user to capture and measure with high magnification and great depth of field. The computer is fully ruggedized and integrated and easily portable with the actual scope. The stage is motorized and allows the computer to control the focus and depth up measuring feature. We didn't use the tilting ability of the stage for what we did here but it has been handy to create three dimensional images or peer into something off axis.

On the mandrel one thing we tried in the shop to gently deburr and soften the edges of the wire groove was wire brushing with a soft bristle wire wheel. The thought was that the bristles would break down the edge and not disturb the groove much.

In this image you can see the effect of the wire brush on the groove. The surface has been roughened by the brush. Unfortunately I didn't get any images before we brushed the mandrel.

Drilling down further at higher magnification we see the edges and lizard skin surface in better detail.

The microscope has a variety of measuring tools for distance, diameter, area etc. One of the more amazing things it can do is three dimensional images. The Keyence VHX does this by taking a set of images depth up and combining them to produce a three dimensional image that can be rotated much like a solid model.

The groove surface and top are both in focus giving a depth of field in this case of around a millimeter at 50x magnification. Images can be stitched together to make a larger seamless mosaic.

This is a three dimensional image of the curved pole section of the test mandrel.

The second thing we tested with this mandrel was a chemical etch to help soften the insulation scuffing corners. It consisted of an acid etch, much the same as a pre-anodizing treatment but without the caustic part of the anodizing process.

In this image you can see the overall improvement of the wire brushed surface in the earlier image.

Link to some other images taken with the VHX system.

Thanks for looking.

Tom Lipton

Thursday, August 8, 2013

A pleasant surprise

For the people that have been following my YouTube channel you already know I recently bought a Clausing drill press. It came from my favorite source, a Craigslist private sale. I have been halfheartedly looking for a variable speed drill press to add to the shop stable. I missed a couple and another one was just too far away for its potential. This one popped up and I happened to be in the mood for a look see. So me and my friend Marty loaded up his truck and headed out.

This one met all my drill press criteria and was still available. As you can see it is all there but dirty. Note the vise and XY slide on the table. It was a bonus with the machine and the subject of this article.

Like the rest of the machine the vise and cross slide unit were dirty and need some TLC. The vise handle was actually welded to the hex on the screw. This vise saw some real Bozon users in its history. So the first step in any refurbishment is to do a lot of cleaning and find all the secrets while you get to know the machine.

Initially I focused on the machine itself to get it in operable condition. This was mostly cleaning and new belts and lubrication of all the moving parts. I shot a series of three videos if your interested in some of the refurbishment details. So after it ran and was tested I started looking at the vise and cross slide that came with it. The vise was a mess. No jaws, drill damage to the nut etc. I consigned myself to just clean it up and set it up for use on the drill press without the cross slide.

Nice one! Not sure how I'm going to fix this one yet. For a week I walked by the vise and scraped for a few minutes then went and did something else. A few nights ago I started to clean in earnest and disassemble the vise. When I got the machine I saw the cross slide unit was a cheapco offshore model so I assumed the vise was from a similar supplier. As I cleaned the vise I saw some casting numbers in the various parts. I had a half thought this was a little weird for a cheap vise.

My next clue that something was strange was when I got a file out to take off some bumps on the center slot. It turns out this is heat treated and hard enough for the file to skate on the surface. By now I was intrigued and kept cleaning. The answer was revealed with the wire brush.

This made everything make sense. Here was my pleasant surprise. As part of the deal I got a four inch vise that costs more new today than I paid for the whole drill press deal. Its a little beat up but easily repairable and will make a good article. For readers out there that don't know Kurt vises. They are the defacto standard machinist vise in the United States for job shops and tool rooms. This particular vise looks old to me for a Kurt. The shape of the coolant drain slots on the side look different than newer Kurt vises and there were no needle thrust bearings in the screw assembly.

You can bet I'll spend a little time getting my new friend back in proper working order.

Thanks for looking.

Tom Lipton

This one met all my drill press criteria and was still available. As you can see it is all there but dirty. Note the vise and XY slide on the table. It was a bonus with the machine and the subject of this article.

Like the rest of the machine the vise and cross slide unit were dirty and need some TLC. The vise handle was actually welded to the hex on the screw. This vise saw some real Bozon users in its history. So the first step in any refurbishment is to do a lot of cleaning and find all the secrets while you get to know the machine.

Initially I focused on the machine itself to get it in operable condition. This was mostly cleaning and new belts and lubrication of all the moving parts. I shot a series of three videos if your interested in some of the refurbishment details. So after it ran and was tested I started looking at the vise and cross slide that came with it. The vise was a mess. No jaws, drill damage to the nut etc. I consigned myself to just clean it up and set it up for use on the drill press without the cross slide.

Nice one! Not sure how I'm going to fix this one yet. For a week I walked by the vise and scraped for a few minutes then went and did something else. A few nights ago I started to clean in earnest and disassemble the vise. When I got the machine I saw the cross slide unit was a cheapco offshore model so I assumed the vise was from a similar supplier. As I cleaned the vise I saw some casting numbers in the various parts. I had a half thought this was a little weird for a cheap vise.

My next clue that something was strange was when I got a file out to take off some bumps on the center slot. It turns out this is heat treated and hard enough for the file to skate on the surface. By now I was intrigued and kept cleaning. The answer was revealed with the wire brush.

This made everything make sense. Here was my pleasant surprise. As part of the deal I got a four inch vise that costs more new today than I paid for the whole drill press deal. Its a little beat up but easily repairable and will make a good article. For readers out there that don't know Kurt vises. They are the defacto standard machinist vise in the United States for job shops and tool rooms. This particular vise looks old to me for a Kurt. The shape of the coolant drain slots on the side look different than newer Kurt vises and there were no needle thrust bearings in the screw assembly.

You can bet I'll spend a little time getting my new friend back in proper working order.

Thanks for looking.

Tom Lipton

Subscribe to:

Posts (Atom)